Wang continues: “Each electric vehicle uses roughly 28,000 grams of lithium in its battery, about 4,000 times as much as the seven grams used in a smartphone. Each hybrid uses roughly 1,900 grams, approximately 270 times as much as a smartphone.”

Near the extinct volcano known as Monte Pissis, high in the Andes on the Chile-Argentina border, the air is thin and animal life scarce. It’s also a prime location for lithium, the silvery-white metal used in the production of lithium-ion batteries.

According to Sam Pelaez, an analyst on our team who recently visited the deposit, the seasonal meltdown of the snowy peaks collects lithium, sodium and other minerals from the soil and underwater hot springs, all of which flows down to the flats and settles—hence the name salt flats or, in Spanish, salares. Over long periods of time, with seasonal temperature variations, the salt builds a crust on top of the “lake,” making for a stunning landscape. Under the crust are high concentrations of lithium.

To extract lithium, Sam says, brine is pumped into large evaporation ponds, resulting in a higher concentration of metals. The brine is then trucked to a facility that extracts the lithium using chemical and metallurgical processes. The lithium carbonate or lithium hydroxide is sold to battery manufacturers, including Tesla.

“It’s possibly the most remote place I’ve ever been to,” Sam says, speaking of the deposit. The 3Q Project, as it’s called, is a five-hour drive from Fiambala, the nearest township, located in Argentina’s Catamarca Province. The province, and the one neighboring it, are known not only for their lithium salt flats but also gold deposits.

The 3Q Project, developed by Toronto-based Neo Lithium, is one of the largest salares discovered in recent decades, with remarkably low impurities when compared to other lithium deposits around the world.

Neo Lithium president and CEO Waldo Perez believes the project has the potential to be considered high-grade.

“The brine found in an open reservoir has the right chemistry for low-cost evaporation process, contains potash as a valuable by-product and lithium grades are equal or superior to all other known undeveloped projects and many producing mines,” Perez says.

41 Million Electric Cars by 2040

This past January, Tesla began mass producing lithium-ion battery cells at its 1.9-million-square-foot Gigafactory in Reno, Nevada. With Panasonic’s cooperation, the company expects to produce a mind-boggling 35 gigawatts of battery power a year by 2018, or about as much as the rest of the world’s current battery capacity combined. (A gigawatt, by the way, is equal to one billion watts.)

Cofounded in 2003 by serial entrepreneur and all-around genius Elon Musk, Tesla is arguably the world’s leading company involved in the production of energy storage units. But it’s certainly not the only one. China’s CATL, or Contemporary Amperex Technology Ltd., is quickly gaining ground and plans to surpass Tesla in terms of battery production by 2020. By that year, close to 85 percent of all lithium-ion batteries in the world will be produced in either the U.S. or China, according to Goldman Sachs, which sees the battery market climbing to $40 billion by 2025.

On a global scale, nearly 40 percent of all lithium supply is used in the production of batteries, including those that power battery electric vehicles (BEVs).

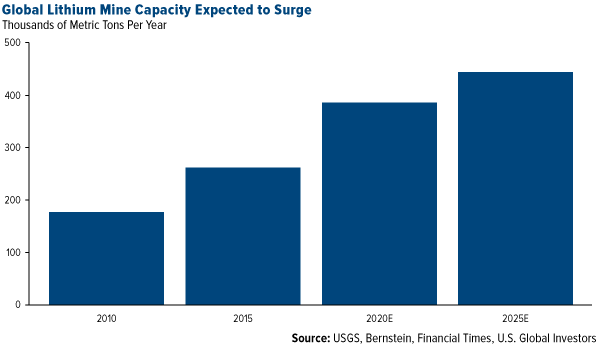

It should come …read more

Source:: Frank Talk

The post Lithium Suppliers Can’t Keep Up with Skyrocketing Demand appeared first on Junior Mining Analyst.